Agnelli

True Classic

Second firing

Dismantled the heater box searching for cooling system leak at the base of the box. That was quick, as the whole unit was just apart. Discovered the repaired stud mount for the heater valve failed, and verified it was the water source by bench testing with running water into the core. Perhaps brazing in a whole new stud will be the permanent fix. Temporarily bypassed the core to enable running the engine to get it tuned. Installed a new cap on the Ducellier distributor. Battery hold down bracket installed, having chased the captive threads on the tray.

Primed the carb then fired the ignition, once the fresh primed fuel ran out, the car didn’t want to run. Inspected the interior of the DCNF and discovered the old/new/varnish mix from the tank was bright green and certainly unfresh. Pumped the remaining 2 gallons from the tank, refilled with 5 gallons fresh premium, cleared the line.

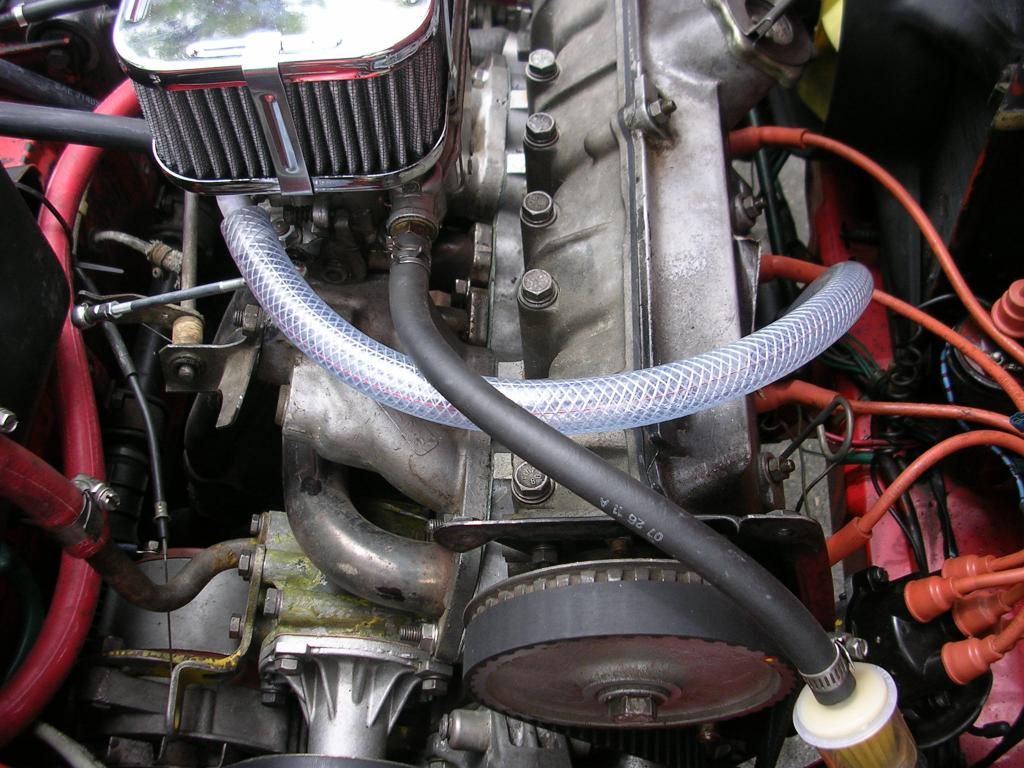

Fired again, this time it would run, strongly, but would starve out. On next to further jet tuning. The emulsifier did not look stock (few huge holes versus many small). That combined with observing the huge jets that came with the DCNF may indicate it came of a race car. Some further research is in order to achieve smooth transitions. Image here of the huge jets that came with the carb. Maiden voyage should be imminent, it idles well. Re-checking valve clearances also in order after first several start ups.

Dismantled the heater box searching for cooling system leak at the base of the box. That was quick, as the whole unit was just apart. Discovered the repaired stud mount for the heater valve failed, and verified it was the water source by bench testing with running water into the core. Perhaps brazing in a whole new stud will be the permanent fix. Temporarily bypassed the core to enable running the engine to get it tuned. Installed a new cap on the Ducellier distributor. Battery hold down bracket installed, having chased the captive threads on the tray.

Primed the carb then fired the ignition, once the fresh primed fuel ran out, the car didn’t want to run. Inspected the interior of the DCNF and discovered the old/new/varnish mix from the tank was bright green and certainly unfresh. Pumped the remaining 2 gallons from the tank, refilled with 5 gallons fresh premium, cleared the line.

Fired again, this time it would run, strongly, but would starve out. On next to further jet tuning. The emulsifier did not look stock (few huge holes versus many small). That combined with observing the huge jets that came with the DCNF may indicate it came of a race car. Some further research is in order to achieve smooth transitions. Image here of the huge jets that came with the carb. Maiden voyage should be imminent, it idles well. Re-checking valve clearances also in order after first several start ups.