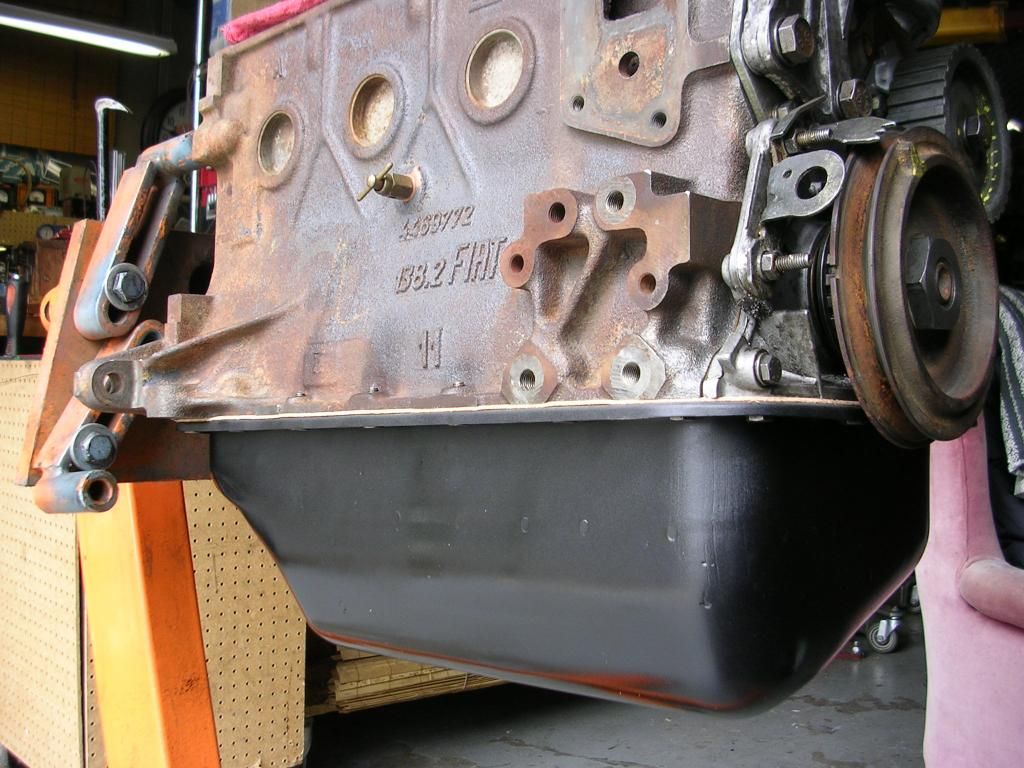

Agnelli

True Classic

Fuel filters / pump

Good feedback on the plastic Fram filters from Karl. After another cycle or so with the temporary filters, then tidy up the system per Greg's post. Replacement already in stock shall be metal Wix in back, then need to source a glass window variant for near the DCNF.

After both filters were replaced, got not fuel pressure to the carb. Disassembled the original OEM pump, the impeller was clear, and the reluctor mechanism did sound like it was operating. Still, no fuel to the carb.

Retrofitted to modern electric in line pump, rated at 2-4.4 PSI. Definitely flows better than the old original.

Yes, that light blue restoration was an Abarth, like the yellow car above.

Good feedback on the plastic Fram filters from Karl. After another cycle or so with the temporary filters, then tidy up the system per Greg's post. Replacement already in stock shall be metal Wix in back, then need to source a glass window variant for near the DCNF.

After both filters were replaced, got not fuel pressure to the carb. Disassembled the original OEM pump, the impeller was clear, and the reluctor mechanism did sound like it was operating. Still, no fuel to the carb.

Retrofitted to modern electric in line pump, rated at 2-4.4 PSI. Definitely flows better than the old original.

Yes, that light blue restoration was an Abarth, like the yellow car above.