Jeff Stich

True Classic

Nice.

Yep, I had thought it might be a close fit. :hmm:

As you say, easy to resolve by just cutting the top of it horizontally with a hacksaw, flush with the top surface of the trans.

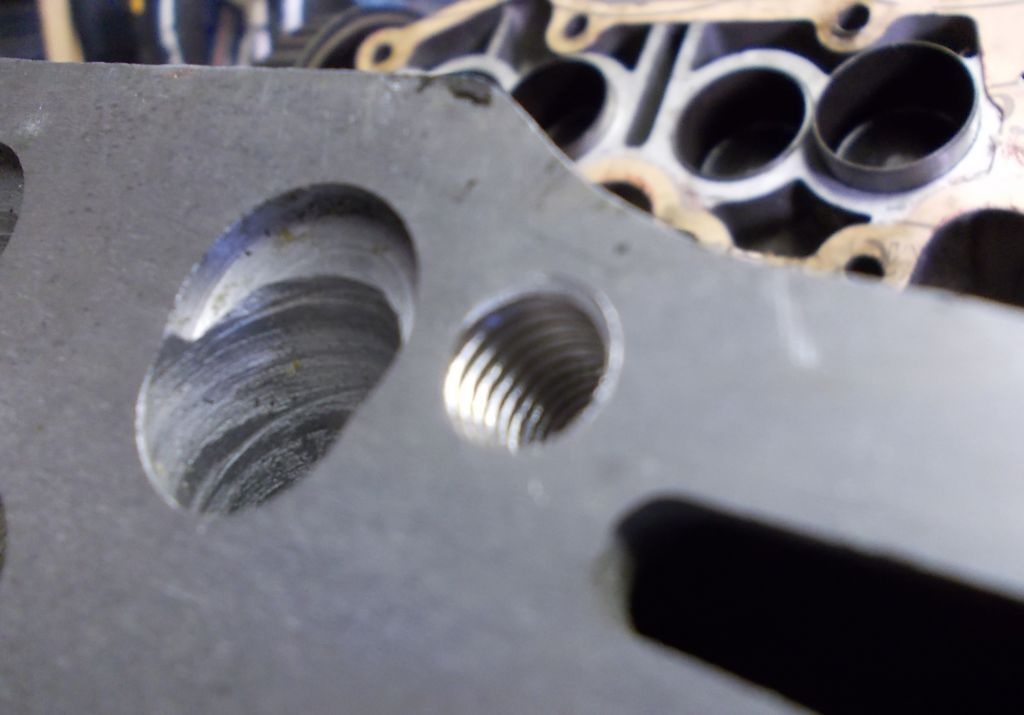

For those who might not be familiar with this part we're talking about, it's basically a thick alloy plate fitted between the main trans casing & the 5th gear extension housing on the driver-side end of the trans. The top end of this plate extends about 1"-2" vertically past the casing to form a mounting "tab" that usually bolts up to a mounting bracket fitted to the driver-side front/inner frame rail of the Yugo. The Yugo does not use an upper "dogbone" mount on the end of the cambox like the 128's & X1/9's do, instead it uses this trans-end mount to "hang" the driver-side end of the driveline. Along with the "normal" mounts on the lower crossmember & upper timing belt area, it's pretty much the same tri-mount set-up as used on the USA Fiat Strada.

Since the 128's don't use this Yugo trans-end mount, Jim won't need the upper "mounting tab" part of this plate, so cutting it off is no big deal (but you can't simply remove the plate, because it still needs to function as a spacer between the trans casing & the 5th gear housing).

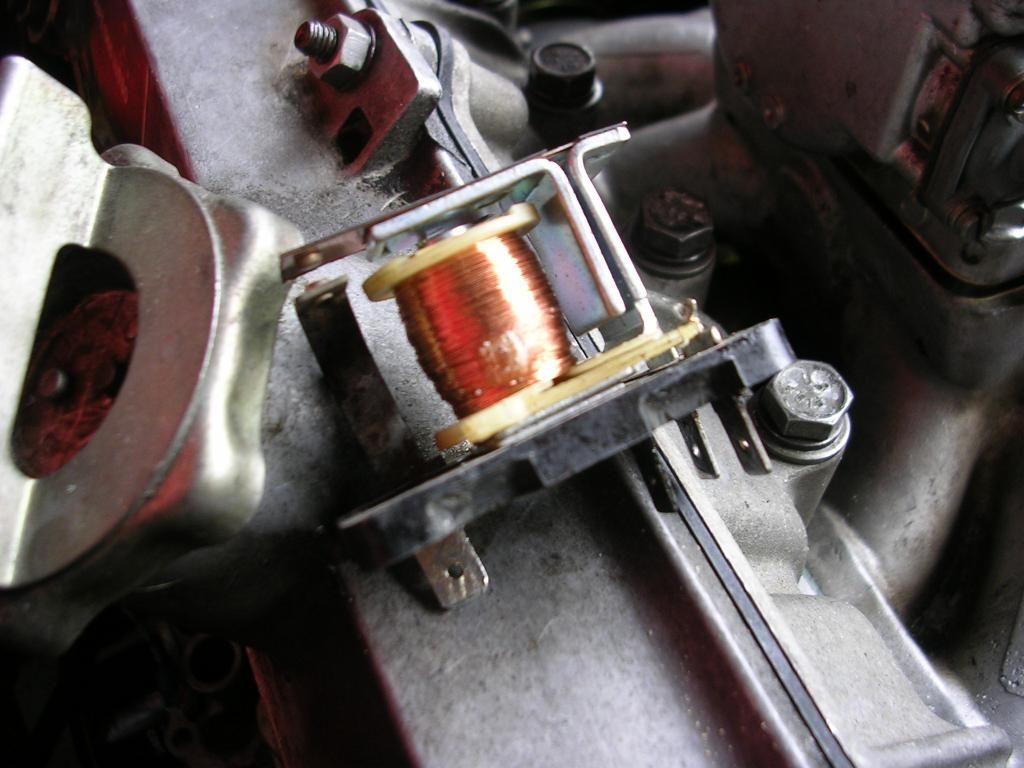

This is the part we're talking about, & where to cut it:

Further to Jeff's question, the Yugo transaxle mounting tab does touch the chassis, though it will be easy to resolve.

Yep, I had thought it might be a close fit. :hmm:

As you say, easy to resolve by just cutting the top of it horizontally with a hacksaw, flush with the top surface of the trans.

For those who might not be familiar with this part we're talking about, it's basically a thick alloy plate fitted between the main trans casing & the 5th gear extension housing on the driver-side end of the trans. The top end of this plate extends about 1"-2" vertically past the casing to form a mounting "tab" that usually bolts up to a mounting bracket fitted to the driver-side front/inner frame rail of the Yugo. The Yugo does not use an upper "dogbone" mount on the end of the cambox like the 128's & X1/9's do, instead it uses this trans-end mount to "hang" the driver-side end of the driveline. Along with the "normal" mounts on the lower crossmember & upper timing belt area, it's pretty much the same tri-mount set-up as used on the USA Fiat Strada.

Since the 128's don't use this Yugo trans-end mount, Jim won't need the upper "mounting tab" part of this plate, so cutting it off is no big deal (but you can't simply remove the plate, because it still needs to function as a spacer between the trans casing & the 5th gear housing).

This is the part we're talking about, & where to cut it: