Matthew

True Classic

I've been planning this project for almost a year and it looks like I'm finally going to start the major portion of the install this weekend. Talking to other X1/9 owners I've found there is a lot of interest in this even among those who have no plans to do it themselves so I thought I'd start a thread documenting what it takes and how it's done.

Today I got baseline numbers on a Mustang Dyno so I'll be able to track the exact changes (hopefully improvements) to the performance. Currently I'm running stock L-Jet without closed loop control (no O2 sensor). The engine has been modified. The bottom end is a stock 1500cc and the head is a shaved (approx .060") 1500cc head ported with a Delta A16 cam set up with 4 degrees advance. I've installed an IAP header with a stock muffler (for now). The engine runs well, pulls strong to 6000 RPM and has excellent low end power. The idle is inconsistent and rough and no amount of adjustment has been adequate in addressing this problem.

Now for pictures because otherwise it didn't happen

The long flat torque curve kind of impressed me but the car has excellent drivability so it didn't really surprise me. Peak HP was 90 which was roughly what I expected. A/F ratios are a bit crazy and MS will solve that problem.

The first order of business will be to clean up this disaster.

I'm going to be removing the entire L-Jet wire harness and replacing it with a new one built from a MS pigtail harness from DIY Autotune. The double relay will be gone and all the unnecessary complexity that goes with it.

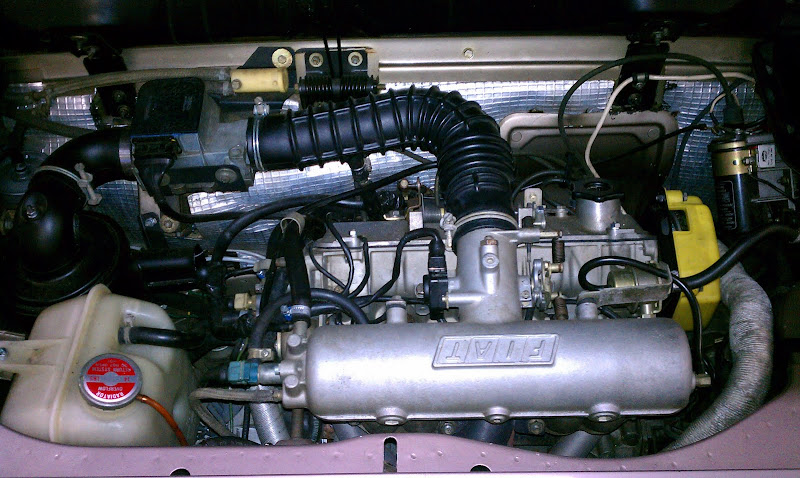

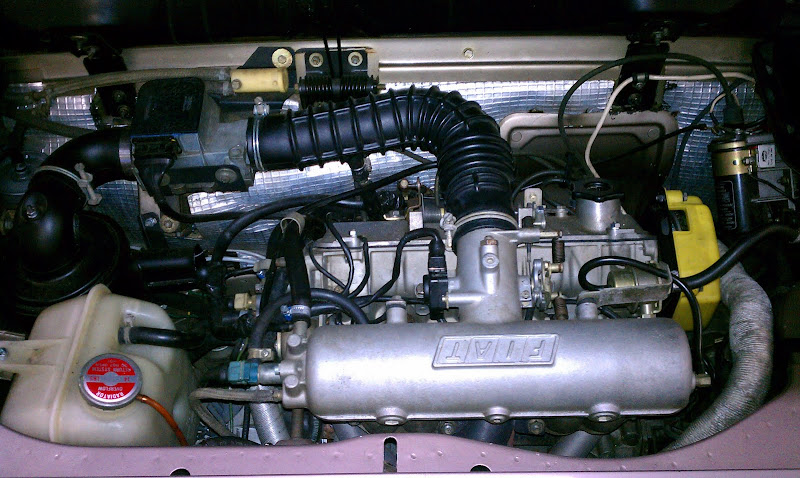

Here is the "before" picture of the engine bay.

More to come. Hopefully in the next few days.

Today I got baseline numbers on a Mustang Dyno so I'll be able to track the exact changes (hopefully improvements) to the performance. Currently I'm running stock L-Jet without closed loop control (no O2 sensor). The engine has been modified. The bottom end is a stock 1500cc and the head is a shaved (approx .060") 1500cc head ported with a Delta A16 cam set up with 4 degrees advance. I've installed an IAP header with a stock muffler (for now). The engine runs well, pulls strong to 6000 RPM and has excellent low end power. The idle is inconsistent and rough and no amount of adjustment has been adequate in addressing this problem.

Now for pictures because otherwise it didn't happen

The long flat torque curve kind of impressed me but the car has excellent drivability so it didn't really surprise me. Peak HP was 90 which was roughly what I expected. A/F ratios are a bit crazy and MS will solve that problem.

The first order of business will be to clean up this disaster.

I'm going to be removing the entire L-Jet wire harness and replacing it with a new one built from a MS pigtail harness from DIY Autotune. The double relay will be gone and all the unnecessary complexity that goes with it.

Here is the "before" picture of the engine bay.

More to come. Hopefully in the next few days.