Hi all,

So here's a quick update about what's been happening in the last, well, year. In the meantime I've started an automotive blog (

www.anygivenreason.com) which has taken up a surprising amount of my time, both hindering progress on the X19 and time spent on Xweb. But it's worth it. And apologies on the quality of the photography - I usually pride myself on trying to take good photos, but lately I just haven't had the time. So most of these are straight off the iPhone!

Okay, so right into it...

It really is the little things that take time, for example we discovered a whole bunch of crud in the fuel tank. Probably spent half a day cleaning it - there's a quarter of a weekend of unplanned time.

X1/9's are a lot easier to work on when there's no interior!

I decided to go for a Crane Hi-6 ignition system, which throws the most ridiculously huge sparks if you pull a plug lead off! The fact that I'll be running fixed seats means the spare wheel well is not usable anyway, so we mounted the ignition system in there.

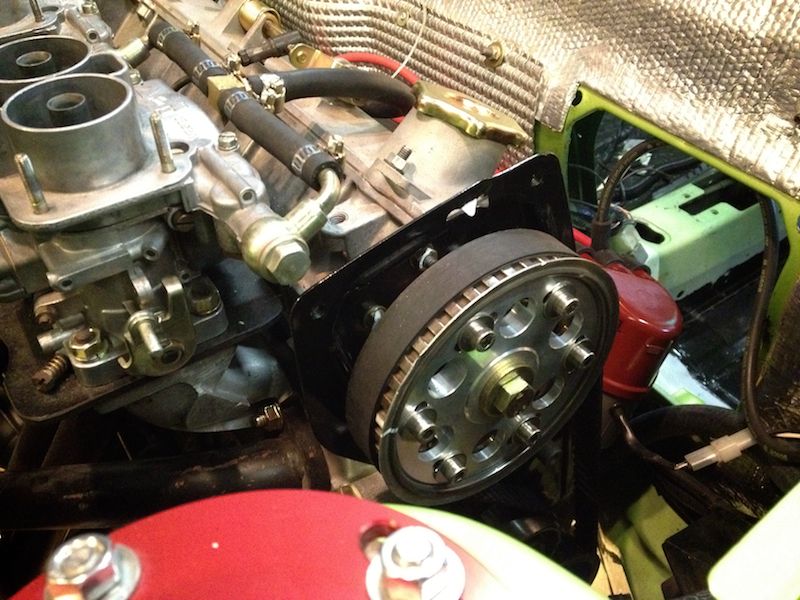

I've honestly lost count of all the little problems we encountered and overcame. This is one for example - when we turned the engine over by hand, the timing belt kept slipping off. I assembled the belt and tensioners and timed the engine according to the workshop manual, but given I'm a bit of a mechanical idiot I was really worried I'd stuffed something up. Turns out this adjustable cam wheel was the wrong one - we switched to a stock one with the correct number of teeth, and all was good.

Getting it started for the first time was a huge step, and a major kick for the project. The engine had sat for probably 2 years since being built with only assembly lube in it and I hadn't even turned it over until just before we fired it (rookie error), so it was a great relief when it didn't just seize into a lump. We didn't smash the champagne bottle over the hull, rather we popped the cork in the shed and had a quiet glass!

http://www.vimeo.com/44094037

We'd just hit the starter for the first time after stuffing around for a bit with incorrect timing. We've since made it sound a damn lot better than it does in this video - the carbs weren't tuned or synced at all, and we discovered that the shafts on the carbies were slightly bent and were binding on the bodies, causing the revs to stick. That was a bit disappointing, because I had the carbies rebuilt at great expense at a well known shop to make sure we didn't have these types of problems. A mate rebuilt them again on our bench, and now they work perfectly.

Once it started we only ran it for about 20 seconds then killed it before it got hot. The exhaust guy had made the exhaust system incorrectly so it rubbed against the driveshafts boots, and (stupid me, yet another rookie mistake) I didn't notice it until a month or so later. He had also welded this god awful chrome tip on without consulting me - he thought it was brilliant and he was really proud, but I didn't have the heart to tell him I hated it. When I had a couple of spare days I took the car to a different exhaust place and got it changed and the system fixed. It was the first time the car had been out and about in a while, and it was good to see it on the road, albeit behind a trailer.

I drive an MX5 daily, so it's a real PITA to transport the X1/9 anywhere at the moment. I have to borrow my girlfriends Dad's 4WD and trailer. They live about an hour from my place, so it's a decent two day exercise to take the X1/9 to a workshop to get anything done. Hence why most of it happens at our place!

The next major hurdle was driving it for the first time. However, in order to do that we had to bleed the brakes and clutch. Those little jobs took close to 6 weeks! Between kinked supply hoses, an incorrect flare (another external shop mistake), a couple of leaky flares and an incorrectly assembled return spring (my fault), I had the pedal box in and out no less than 8 times! It also leaked brake fluid all over my hands and face, and my freshly painted floor - which will now need to be painted again.

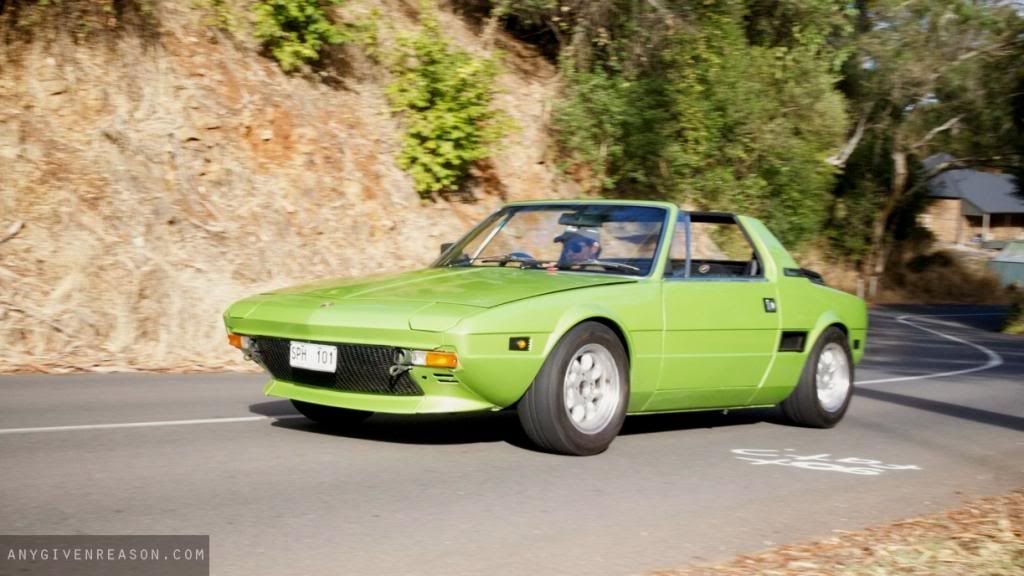

But it did feel good to finally drive it for the first time in over 4 years. Nothing was adjusted, so it was actually pretty awful in all honesty. But it did verify that the car moved under its own power and that the gearbox we built ourselves worked, so it was a success from that point of view.

However shortly after the gearbox starting leaking expensive Redline gearbox oil everywhere. We had to fix it, so out came the gearbox again in just under 2 hours! We found a couple of burs that we'd missed on the casings, and we reassembled it with new gaskets and a much better sealant - so far so good!

It was here that the X19 made it's first serious attempt at killing me. As I was removing the box, it fell off the input shaft onto the ground, landing on top of my arm. Somehow my arm ended up in the valley created between the main casing and diff housing. It got a little bruised, but it very easily could have been broken. Lucky.

Finding seats to fit my 6.3" frame into the X1/9 has been a huge headache. The back of my head rubs on the targa bar with stock seats (not ideal), and all race seats just exacerbate the problem as they sit you more upright. I tried no less than 8 different seats, and none of them fit. I was about to resort to lowering the floor...

... when a friend called and said he had some old seats he was taking out of his Mini Cooper S rally car. I despondently tried them, and to my great surprise, I actually fit! They are

extremely reclined which means my head now sits about 2-3" under the targa bar. It's a seriously cool driving positon - my shoulders are only just above the tops of the doors, and I peer out over the steering wheel which is now perfectly placed, along with the gears, for taller people. It's very difficult to get in and out, so I may need to look into a detachable steering wheel boss somewhere down the line.

I drilled the stock seat rails out, and my friend Michael did an awesome job of mounting them as low as we could get them.

This is how we work through an Australian summer! Sorry ladies, he's taken.

The only problem with the new driving position is that I simply couldn't operate the column stalks - my knees brushed them even when not in use. We looked into relocating the switches, but the solution in the end was devilishly simple, if extremely time consuming. Michael modified the stalks to clear my knees!

When the guys did the body I got them to weld up the holes under the headlights so I could go bumperless. Unfortunately we later discovered (after paint) that the headlights didn't quite fit anymore as the angles were slightly wrong. With some trepidation we attacked my new paint job with the files to make the headlights fit, which they now do perfectly. And what's more, we touched it up with a spray can of the correct colour and you can hardly tell if you don't know what you're looking for. I'll fix it properly one day, but this will do for now.

I decided to get busy on the interior, and taught myself how to trim with vinyl and spray glue. Tip for newbies - spray glue goes absolutely everywhere if you're not careful.

In the end I was pretty happy with how it turned out, not bad for a newbie although it did take a serious amount of time to do. The bits at the end were waaaaay better than my first bits and if I did it again it would be a much better job, but I guess that's always the case. I don't know how much a motor trimmer would charge for this, but all it cost me was about $100 in materials and two weekends.

While I was at it I made some door cards. I'm going for a vintage racer look, and I think these fit the bill quite nicely. I'm just waiting on a leathersmith to finish making the pull handles out of old, worn leather - Magnus Walker style.

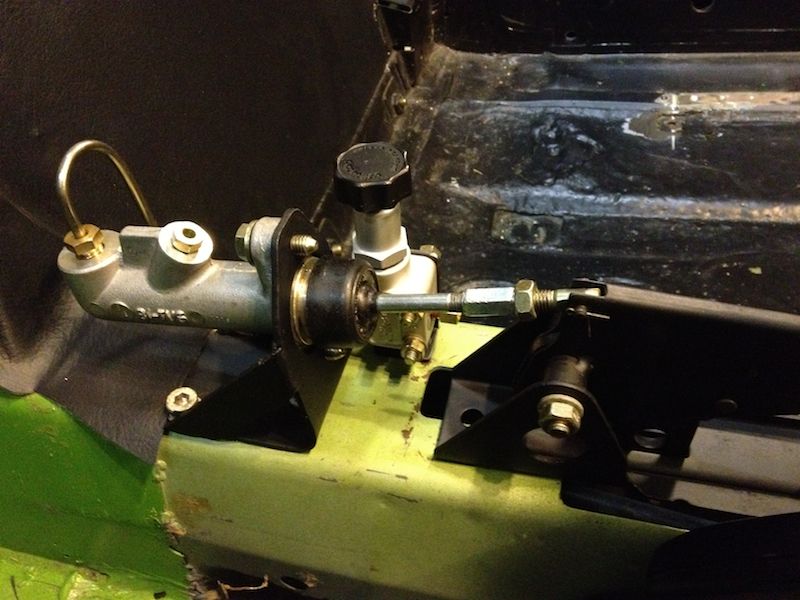

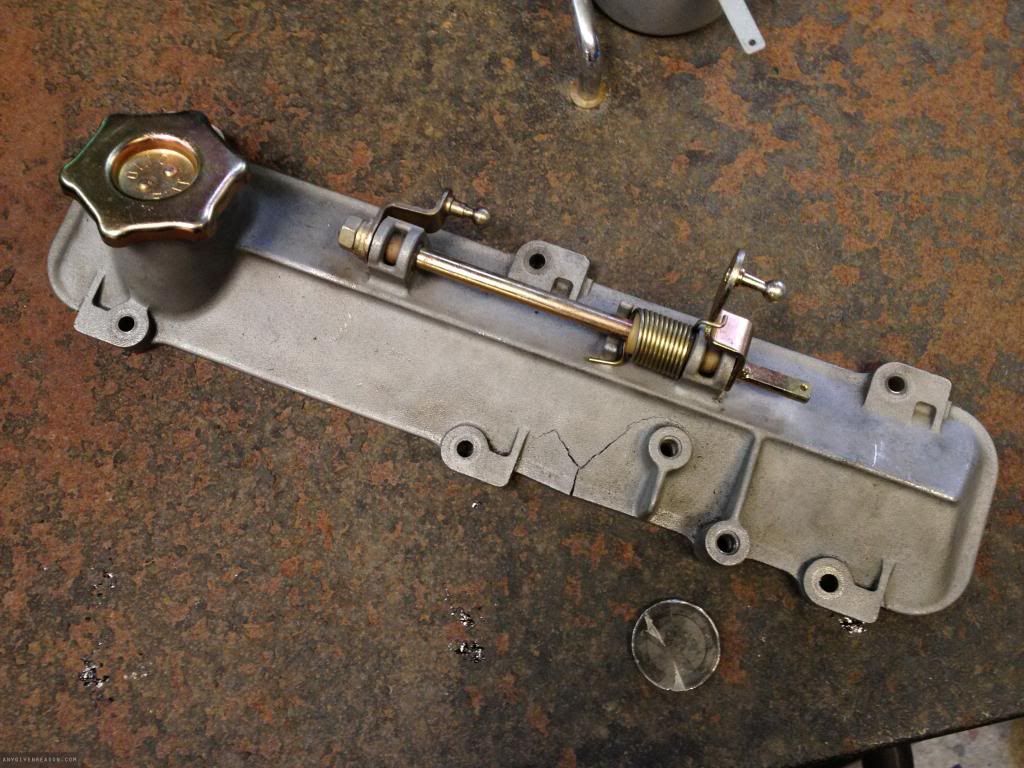

I'm running the Wilwood 4 piston calipers front and rear, which don't have a handbrake mechanism. The only way is to make a hydraulic setup, which will be fantastic for handbrake turns too. We modified an Alfa 33 handbrake cradle to actuate the cylinder, and also mounted the Wilwood bias valve here too. It's not plumbed up in this photo - waiting on some fittings I forgot to get. Once again this setup is more of Michael's handiwork - a full day in this alone. But the ones the race shops sell here are about $500, and this whole setup cost just under $150.

Last weekend it was time for the final checkover of everything mechanical to make sure it's all tight and that I didn't assemble anything incorrectly, which I did. But all fixed now!

My Dad made up this wheel alignment setup so we could put a baseline setting through everything, until I get it properly checked. One day soon I'll need to learn how to do this properly from home - there's so much adjustment on these cars from the factory plus the G Force suspension I'm running, that it will get too expensive having to pay for an align every time we want to change something. I need to make friends with someone who owns a set of corner weight scales, too.

With everything checked and adjusted we did a couple of laps of our (very short) driveway, and it feels worlds different. I wanted to take it around the block but it still doesn't have a windscreen or a dash in it, and Dad convinced me that the cops probably wouldn't see the funny side if I got picked up. It would suck to have the car defected before it's even finished! But I can't wait for the first drive, I think it's going to be really good.

So I set about finding a windscreen, and found my old one with my old scruitineering stickers from about 6 years ago still stuck to it. This car was bog stock back then, and if I remember correctly, overheated on at least one of those track days. I'm getting the same windscreen put back in, so fingers crossed we can fill it with plenty more stickers in the future!

And this is where we sit at the moment - my X1/9 is nearly done, and my parts are slowly overtaking my poor Dad's shed. He's been really great through this, pretty much putting his projects on hold until my car is done.

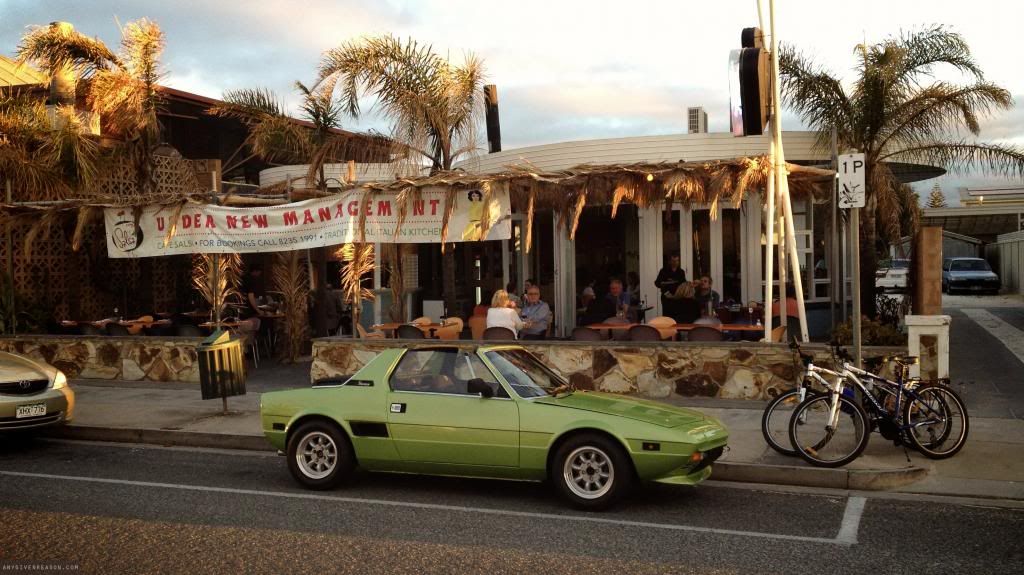

Okay, here's one proper photo to finish off with. Thanks for reading (if you haven't already dozed off!), and I'll make sure to keep this more regularly updated as we get in to actually driving the car and ironing the bugs out.

Cheers, Andrew