sdlsaginaw

Steven Lawson

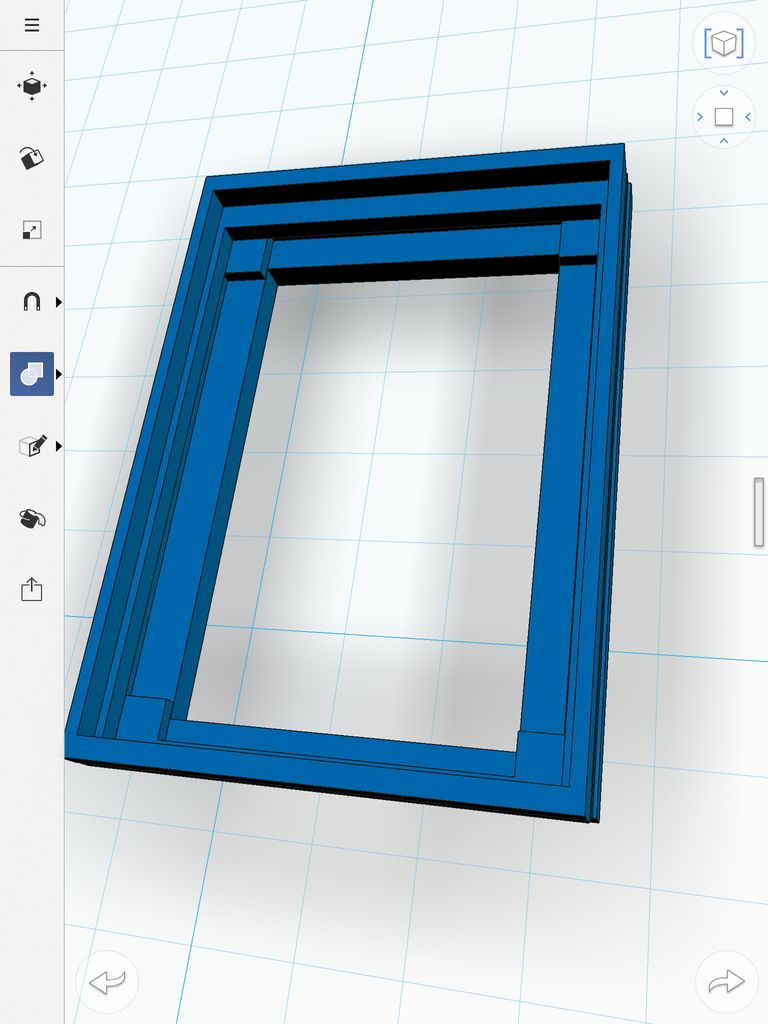

Anyone interested in printing a part for me?

It's supposed to be a box I'll glue on top of an early switch bucket to house a uLCD-144-g2 display. It's only a tiny bit larger than the switch bucket.

It's my first attempt at a design and it kinda sucks. I'm using 123D Design on the iPad. I made four individual layers and carefully measured and removed the areas inside each layer. Upon stacking the layers nothing lined up. :mad4: I ended up adjusting the layers so the inside would be ok and I'll have to sand the outside surfaces flat again.

The idea is I dremel a channel in the back to glue a switch bucket, glue the display to the four pads inside, then glue in a masked off clear piece of plastic in the top.

I've never tried this before so I have no idea if this is even printable. The software can export an STL file.

I'd hope to get a printer at some point if I ever get past the learning curve of the drawing aspect.

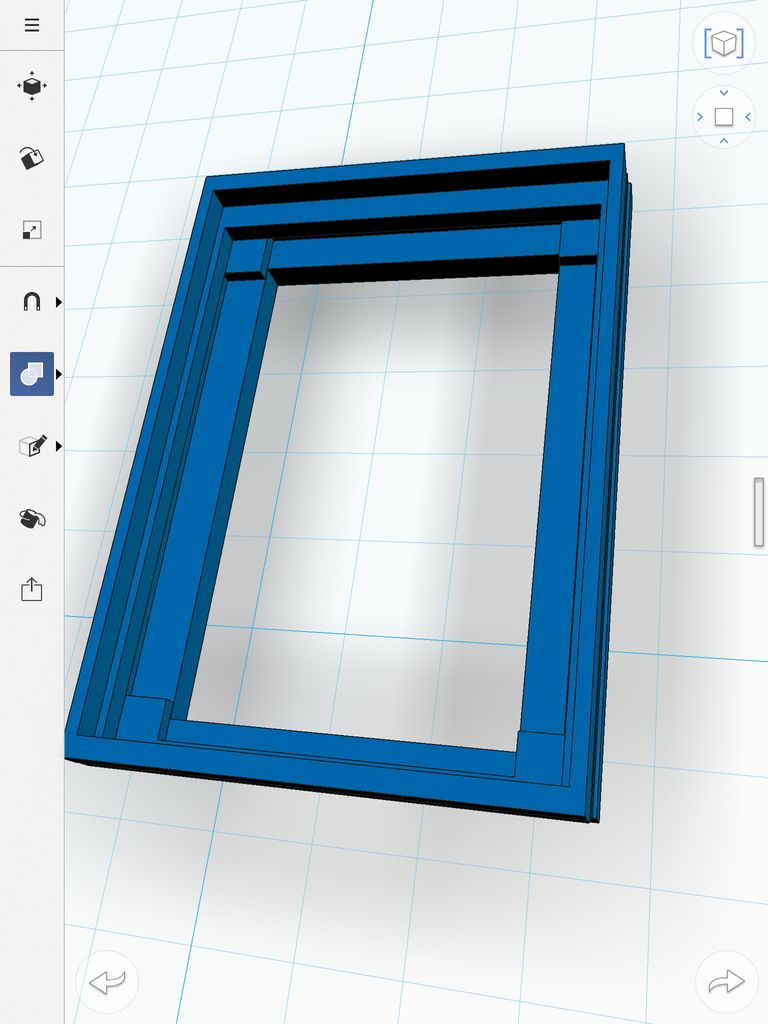

It's supposed to be a box I'll glue on top of an early switch bucket to house a uLCD-144-g2 display. It's only a tiny bit larger than the switch bucket.

It's my first attempt at a design and it kinda sucks. I'm using 123D Design on the iPad. I made four individual layers and carefully measured and removed the areas inside each layer. Upon stacking the layers nothing lined up. :mad4: I ended up adjusting the layers so the inside would be ok and I'll have to sand the outside surfaces flat again.

The idea is I dremel a channel in the back to glue a switch bucket, glue the display to the four pads inside, then glue in a masked off clear piece of plastic in the top.

I've never tried this before so I have no idea if this is even printable. The software can export an STL file.

I'd hope to get a printer at some point if I ever get past the learning curve of the drawing aspect.