jvandyke

True Classic

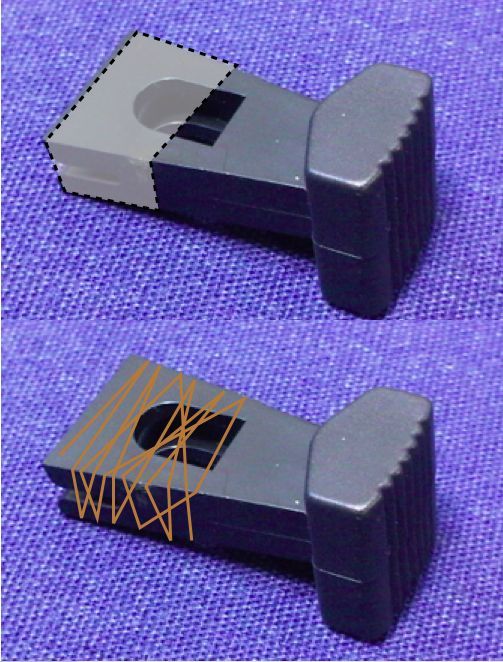

Last night I broke two of my (non A/C) heater control lever knobs. I was so careful for years but it was just too darn cold out there, should have stopped and broke out the hair dryer but didn't.

So I'm thinking of trying some sort of casting to reproduce them, not just for me but for other hamfisted Xers. Looking for ideas for how/what to use to try and recast them in plastic, or better a flexible version of plastic! I'm thinking clear so I can light them, then black out what I don't want lit, but also just making straight black for every one else. Ricardo would know methinks.

So I'm thinking of trying some sort of casting to reproduce them, not just for me but for other hamfisted Xers. Looking for ideas for how/what to use to try and recast them in plastic, or better a flexible version of plastic! I'm thinking clear so I can light them, then black out what I don't want lit, but also just making straight black for every one else. Ricardo would know methinks.

Last edited: