Still not happy with clutch operation. Last inch of pedal is where all the action takes place and though it works just don't like the feel of it. Decided to play with it last night and attempted to redo my mod for even more "bend" but didn't move it much, ended up the same. Removed the pedal stop, bleed the system (although I never cracked it open, I lost the pedal completely at one point.

Bottom line is I have to extend the adjustment on the slave rod all the way out, almost nothing sticking out other side of lever. (see picture above)

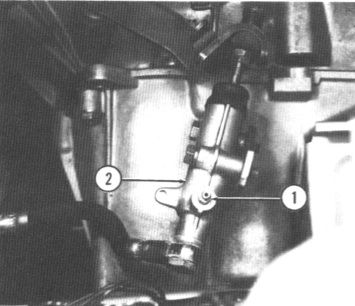

Makes me wonder if I don't have a mis matched part or slave is put on wrong. The bracket only goes one way, I know you can put it fore/aft of the "tab" on the gearbox but I think it only works one way. This picture shows lots of rod sticking out with the spring thing and all, I don't have anywhere near that despite the clutch lever being moved. Ideas? I'll check the position of the slave against pictures later today, probably really late.

BTW

there is a lot of slop in the lever, there's tons of play before the lever actually makes the TO bearing touch the pressure plate, I assume that's normal? I'm trying to set it up so all (but a fraction) of that play is dialed out but by then the clutch system is out of travel on full pedal. I suppose I could just mock up an extended clutch slave rod to test things, just a threaded rod would suffice for testing I suppose

4th picture down, I have WAY more exposed rod between the slave and the lever but lever looks like it's about the same position, meaing the slave may be mounted wrong......

http://xwebforums.org/showpost.php?p=150550&postcount=44